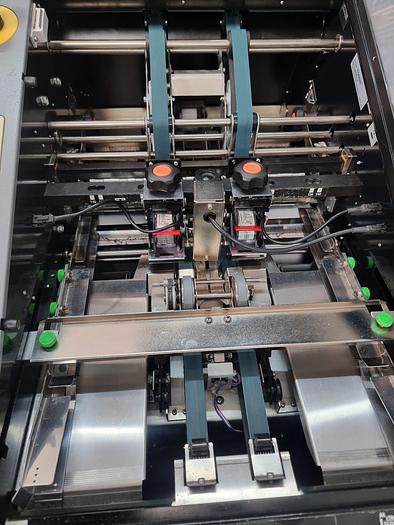

Duplo bookletmaker with Automatic Sheet Feeder

Duplo bookletmaker with Automatic Sheet Feeder

£4,500 (GBP)

Location:United Kingdom

Description

Duplo DBM-120 Bookletmaker with sheet feeder for pre collated digital print Duplo DBM-120 Automatic Bookletmaker Features Include - Booklet capacity of up to 20 sheets (100 pages) of 20-lb. stock. - Block capacity of up to 30 sheets of 20-lb stock. - Production speeds of up to 1800 booklets per hour can be achieved. - Programmable with 10 pre-set & three custom sizes - Corner, Side or Regular Booklet Stapling - Can be used used without staple head to fold up to 20 sheets in half - Connects to the Duplo DSF-2000 Set Feeder & DBM-120T Automatic Trimmer. A4 Sheet Speed Max 120 Sheets/Min A4 Booklet Production Max 40 Books/Min A3 Booklet Production Max 30 Books/Min Typical Hourly Production 5 Sheet A4 5800 sheets (= 194 ppm) 5 Sheet A3 4500 sheets (= 300 ppm) Programmes 10 pre-set sizes / 3 custom sizes Sheet Sizes(Min) 279mm x 210mm Sheet Sizes(Max) 457mm x 320mm Booklet Sizes (Min) length 140mm (before trim) x 210mm Booklet Sizes (Max) length 229 (before trim) x width320mm Capacity (80gsm) 20 sheets (with grain) Stitch/Staple Type 2 x Staple (from 2 x 5000 staple cartridge)

The Duplo System 2000 is a versatile and efficient booklet making system designed for producing high-quality booklets quickly and easily. This system is commonly used in print shops, in-house print departments, and other environments where there's a need for rapid production of booklets, brochures, and other multi-page documents. Here are some key features and components typically associated with the Duplo System 2000:

- Modular Design: The system often comprises several modules that can be configured according to specific needs. Common modules include collators, stitchers, folders, and trimmers.

- Collators: These gather and organize printed sheets into sets. Collators can handle various paper sizes and types, ensuring each booklet's pages are correctly ordered.

- Stitchers: Stitching (stapling) modules can staple the gathered sets along the spine, creating a booklet. Some systems offer multiple stitching heads for different configurations.

- Folders: After stitching, the booklet needs to be folded. Folding modules in the System 2000 ensure precise and consistent folding, essential for professional-looking booklets.

- Trimmers: The trimmer module trims the edges of the folded booklets for a clean finish. This step is crucial for removing any uneven edges that result from the folding process.

- Automation and Integration: The System 2000 is known for its high degree of automation, which reduces manual labor and increases productivity. The system's modules are typically integrated, allowing seamless operation from start to finish.

- User-Friendly Interface: Many models come with an intuitive control panel that makes it easy for operators to set up and run jobs with minimal training.

- High Production Speed: Designed for efficiency, the Duplo System 2000 can produce a large number of booklets in a short time, making it ideal for environments with high demand.

- Flexibility: The system can handle a variety of booklet sizes, paper weights, and configurations, providing flexibility to meet different customer requirements.

- Quality Output: Known for producing high-quality finished products, the System 2000 ensures that each booklet is professionally stitched, folded, and trimmed.

These features make the Duplo System 2000 a popular choice for businesses that need reliable, efficient, and high-quality booklet production capabilities.

4o

Specifications

| Manufacturer | Duplo |

| Model | dbm120 |

| Condition | Used |

| Stock Number | 2597 |