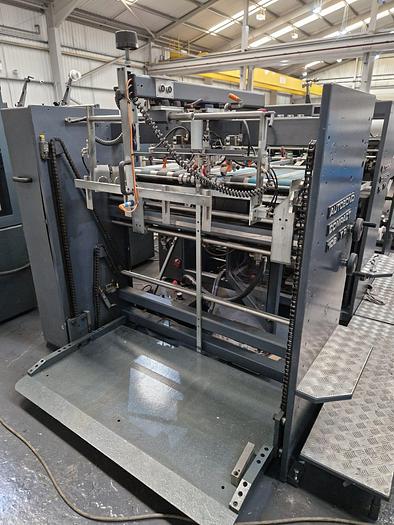

2005 AUTOBOND 102TP Thermal Laminator, Sheet Size 102 x 76cm, Heidelberg Deep Pile Stream Feeder, Double Sided Laminator, 2 x Film Unwinds, Auto Sheeter, Deep Pile Stacker Delivery

2005 AUTOBOND 102TP Thermal Laminator, Sheet Size 102 x 76cm, Heidelberg Deep Pile Stream Feeder, Double Sided Laminator, 2 x Film Unwinds, Auto Sheeter, Deep Pile Stacker Delivery

£42,000 (GBP)

Location:Lancaster, United Kingdom

Description

2005 AUTOBOND 102TP

Thermal Laminator, Sheet Size 102 x 76cm, Heidelberg Deep Pile Stream Feeder, Double Sided Laminator, 2 x Film Unwinds, Auto Sheeter, Deep Pile Stacker Delivery

An Autobond laminator is a type of industrial machine used for laminating printed materials such as books, magazines, brochures, and packaging. Autobond is a well-known brand in the laminating industry, recognized for its high-quality, durable, and efficient laminating equipment. These machines can handle a variety of substrates and laminating films, providing a protective and aesthetic finish to printed products.

Key Features of Autobond Laminators

- High-Speed Operation: Autobond laminators are designed for high-volume production, capable of processing large quantities of material quickly and efficiently.

- Versatility: They can laminate a wide range of materials, including paper, cardstock, and certain types of plastics, using various types of laminating films such as gloss, matte, and special finishes.

- Precision: These machines offer precise control over temperature, pressure, and speed, ensuring consistent quality across different production runs.

- Automation: Many Autobond laminators come with automated features such as feeder systems, film application, trimming, and stacking, which reduce manual intervention and increase productivity.

- Durability: Built with robust components, Autobond laminators are designed for long-term use in demanding production environments.

- Customizability: They often come with options and accessories that allow for customization based on specific production needs, such as different film widths and additional finishing capabilities like embossing or spot UV coating.

Common Uses

- Commercial Printing: Laminating book covers, magazine covers, posters, and other printed materials to protect them from wear and tear.

- Packaging: Providing a protective and visually appealing finish to product packaging.

- Advertising Materials: Enhancing the durability and look of brochures, flyers, and other marketing collateral.

Benefits

- Protection: Laminated materials are more resistant to moisture, scratches, and other types of damage.

- Appearance: Laminating can enhance the visual appeal of printed materials, giving them a professional and polished look.

- Longevity: Extends the life of printed materials by protecting them from environmental factors and handling.

Specifications

| Manufacturer | autobond |

| Condition | Used |

| Stock Number | 2616 |

| Current state | In stock |